-

Send us a mail [email protected]

-

Call us anytime +91-9999884400

The process of creating this syrup has evolved over the years, with modern machinery offering greater efficiency and consistency. One of the most important machines in this process is the invert sugar syrup making machine. In this blog post, we’ll explore what an invert sugar syrup making machine is, how it works, and why it is essential for food production.

What Is Invert Sugar Syrup?

Invert sugar syrup is a mixture of glucose and fructose that is created by hydrolyzing sucrose (table sugar). The process of hydrolysis breaks down sucrose into its two components: glucose and fructose, which are sweeter and have different physical properties than regular sugar. This syrup is widely used in the food industry, particularly in the production of candies, baked goods, ice cream, beverages, and more.

The main benefit of invert sugar syrup is its ability to retain moisture, making it a common ingredient in products that need to remain soft or have a long shelf life. Additionally, invert sugar syrup has a smoother texture than granulated sugar, contributing to the creaminess and consistency of many food products.

The Invert Sugar Syrup Making Machine: A Brief Overview

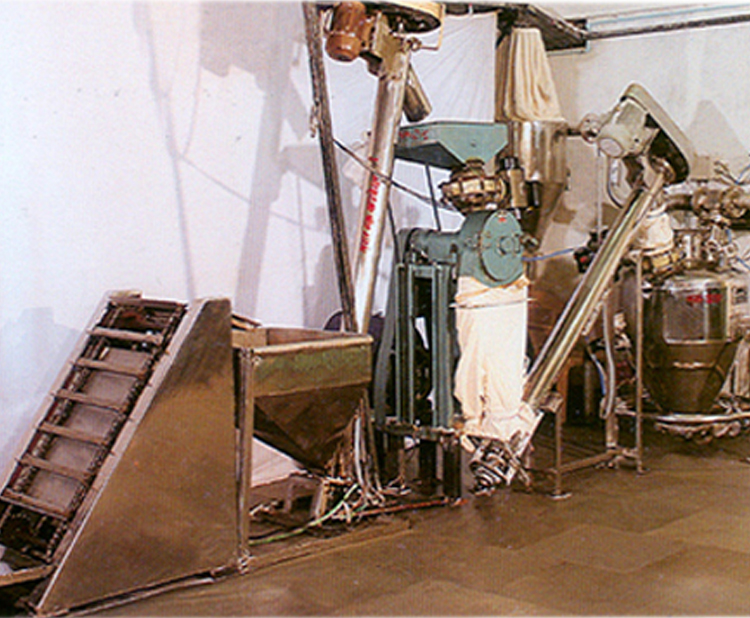

An invert sugar syrup making machine is a specialized piece of equipment designed to produce invert sugar syrup from sucrose. It typically involves a combination of heating, acid treatment, and controlled mixing to break down sucrose molecules into glucose and fructose. The machine often uses a carefully controlled environment to ensure that the syrup’s consistency and sweetness are optimized for use in various food applications.

These machines are commonly found in large-scale food production facilities, where there is a need for consistent, high-quality syrup production. The invert sugar syrup making machine helps manufacturers maintain a steady supply of syrup, ensuring that the desired properties are met for each batch of product.

How Does the Invert Sugar Syrup Making Machine Work?

The process of making invert sugar syrup with an invert sugar syrup making machine involves several steps, which can be summarized as follows:

1. Heating: Sucrose syrup is heated to a specific temperature to initiate the hydrolysis process.

2. Acid Addition: An acid, such as citric acid or tartaric acid, is added to the mixture to help break the chemical bond between glucose and fructose.

3. Hydrolysis: The combination of heat and acid catalyzes the breakdown of sucrose into its two components, glucose and fructose. The reaction is carefully monitored to ensure the correct ratio of glucose to fructose.

4. Cooling and Filtration: Once the hydrolysis is complete, the syrup is cooled and filtered to remove any impurities and ensure that the syrup is clear and smooth.

5. Final Adjustments: The syrup may undergo additional processes to adjust its sweetness, viscosity, and clarity, ensuring it meets the desired specifications for use in food production.

The invert sugar syrup making machine is designed to automate this entire process, ensuring consistency and efficiency. With precise control over temperature, pH levels, and reaction time, these machines help food manufacturers produce high-quality syrup in large quantities.

Why Is the Invert Sugar Syrup Making Machine Important for Food Production?

An invert sugar syrup making machine offers several key advantages for food manufacturers:

1. Consistency and Quality: One of the main reasons food manufacturers rely on these machines is the ability to produce syrup consistently. The machine’s precise control over temperature, acid concentration, and reaction time ensures that every batch of syrup meets the required standards for sweetness, texture, and moisture retention.

2. Efficiency: The automated nature of the invert sugar syrup making machine significantly improves production efficiency. Instead of relying on manual methods, which can be time-consuming and prone to errors, the machine speeds up the syrup-making process and reduces labor costs.

3. Customization: The machine allows for precise adjustments to the final product. Food manufacturers can alter the ratio of glucose to fructose, modify the syrup’s viscosity, and control other characteristics to tailor the syrup to specific products. This level of customization is crucial in industries where product consistency and quality are paramount.

4. Cost Savings: By improving efficiency and reducing labor costs, the invert sugar syrup making machine helps food manufacturers save money in the long term. Additionally, the syrup’s long shelf life and moisture-retention properties reduce waste in the final products, leading to further cost savings.

5. Scalability: These machines are designed to handle large-scale production, which is essential for food manufacturers who need to produce invert sugar syrup in bulk. Whether a company is producing small batches or large quantities, the invert sugar syrup making machine can scale up production to meet demand.

Applications of Invert Sugar Syrup

Invert sugar syrup is used in a variety of food products, and the invert sugar syrup making machine plays a key role in ensuring that manufacturers can produce high-quality syrup for these applications. Some of the most common uses for invert sugar syrup include:

● Candy and Confectionery: Invert sugar syrup is commonly used in the production of candies, caramels, and chocolates. It helps maintain a smooth texture and prevents crystallization, contributing to the candy’s chewiness and quality.

● Baked Goods: In cakes, pastries, and bread, invert sugar syrup helps retain moisture, keeping the final product soft and fresh for longer periods.

● Ice Cream: Invert sugar syrup enhances the texture and mouthfeel of ice cream, preventing ice crystals from forming and contributing to a creamier, smoother consistency.

● Beverages: In soft drinks, syrups, and alcoholic beverages, invert sugar syrup is used to improve sweetness, texture, and solubility, especially in cold temperatures.

● Preserves and Jams: Invert sugar syrup helps preserve fruit-based products by preventing crystallization and maintaining the texture and flavor of the product.

The versatility of invert sugar syrup makes it an essential ingredient in numerous food products, and the invert sugar syrup making machine ensures that these products are consistently high-quality.

Choosing the Right Invert Sugar Syrup Making Machine

When selecting an invert sugar syrup making machine, food manufacturers need to consider several factors, including:

1. Capacity: The machine should be able to meet the required production volumes, whether for small batches or large-scale production.

2. Customization Features: Look for machines that offer precise control over temperature, acid addition, and other parameters to allow for customization of the syrup’s properties.

3. Ease of Maintenance: Regular maintenance is essential to keep the machine running smoothly. Choose a machine that is easy to clean and maintain to ensure long-term reliability.

4. Energy Efficiency: Energy-efficient machines can help reduce operational costs and improve sustainability.

Investing in the right invert sugar syrup making machine is crucial for manufacturers who wish to produce high-quality syrup efficiently and cost-effectively.

Conclusion

The invert sugar syrup making machine plays a critical role in the food production process, offering manufacturers the ability to create high-quality syrup in a consistent, efficient, and cost-effective manner. Whether it’s for use in candies, baked goods, ice cream, or beverages, invert sugar syrup is a key ingredient in many food products. By investing in a reliable and high-performance invert sugar syrup making machine, manufacturers can enhance product quality, improve production efficiency, and meet consumer demand for delicious, high-quality food products.