-

Send us a mail [email protected]

-

Call us anytime +91-9999884400

These machines are not only essential for producing high-quality invert syrup but also play a pivotal role in enhancing productivity, hygiene, and overall output standards.

Invert sugar syrup is a liquid sweetener produced by hydrolyzing sucrose into its two components: glucose and fructose. The resulting syrup is sweeter than regular sugar, with a smoother texture and better solubility. It’s widely used in industries like confectionery, bakery, beverages, pharmaceuticals, and even dairy. Manufacturers prefer invert syrup because it prevents crystallization, improves moisture retention, and enhances the shelf life of products.

However, achieving the perfect balance of sweetness and texture in invert syrup depends significantly on the machinery used in the production process. This is where modern invert sugar syrup machines come into play.

Traditional methods of making invert syrup involved manual processes, inconsistent heating, and longer production times — all of which impacted quality and scalability. As global demand for refined sugar alternatives surged, manufacturers needed a smarter, faster, and more hygienic approach.

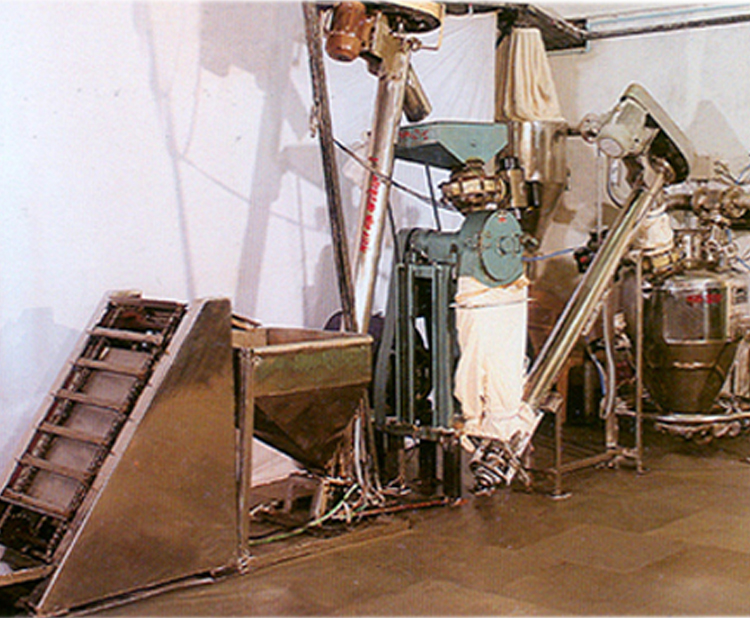

Invert sugar syrup making machines answered that call by offering automated, precision-controlled production lines that reduce human error, maintain product consistency, and boost overall efficiency. These machines combine controlled temperature regulation, automated pH adjustment, mixing, filtration, and even sterilization features — all under one system.

Invert sugar syrup making machines provide precise control over key production parameters like temperature, pH, and mixing speed. This ensures consistent quality in every batch, delivering syrup with the perfect texture, sweetness, and stability.

2. Increased Production Efficiency

By automating the syrup-making process, these machines significantly reduce manual labor and production time. This leads to faster output, higher volumes, and greater overall production efficiency, enabling manufacturers to meet growing demand.

3. Reduced Wastage and Improved Yield

The accuracy of invert sugar syrup machines helps minimize syrup wastage by optimizing raw material usage. Manufacturers can extract more from the same amount of ingredients, leading to better yields and cost savings over time.

4. Energy Savings

Modern machines are designed with energy-efficient features like insulated heating chambers and optimized heating systems. This reduces electricity consumption, making the syrup production process more cost-effective and environmentally friendly.

5. Enhanced Hygiene and Food Safety

Invert sugar syrup making machines are typically constructed from food-grade stainless steel and feature easy-to- clean designs. Many also include built-in filtration and sterilization systems to ensure the syrup is produced in a hygienic environment, meeting strict food safety standards.

For any reputable manufacturer, delivering a consistently high-quality product is crucial to maintaining brand reputation and meeting strict food safety regulations. Poorly produced invert syrup can result in off-flavors, improper viscosity, contamination risks, or premature spoilage.

That’s why the right invert sugar syrup making machine is not just a production tool — it’s a quality control instrument. These machines ensure:

• Accurate temperature and pH control, which is essential for the precise inversion of sugar.

• Uniform mixing to maintain consistent syrup texture.

• Sanitary design to avoid contamination during production.

• Batch tracking and automation, which help meet compliance standards.

• Scalability, allowing small and large manufacturers alike to expand production without compromising on quality.

When top manufacturers invest in an invert sugar syrup making machine, they’re not just buying hardware — they’re investing in reliability. The best machines on the market offer:

• Stainless steel, food-grade construction for maximum hygiene.

• Automated control panels with programmable settings for different syrup grades.

• Energy-efficient heating systems to reduce operational costs.

• Built-in filtration and sterilization modules to ensure purity.

• Easy-to-clean designs, reducing downtime between batches.

By prioritizing these features, manufacturers can produce invert syrup that meets global food safety and quality standards — whether it’s for domestic use or export.

Many manufacturers have reported significant gains after switching to automated invert syrup production systems. What once took hours of manual labor and guesswork can now be done in minutes with greater precision.

In terms of cost-effectiveness, using an invert sugar syrup machine reduces raw material wastage, cuts down labor costs, and minimizes the chances of batch failure. The energy savings from modern, insulated heating chambers and optimized mixing speeds further reduce overheads, making these machines an economically sound investment.

Most importantly, the consistency of output allows manufacturers to build trust with their clients and end consumers — ensuring every batch of candy, cookie, soft drink, or syrup-based product tastes just like the last.

Technology and trust go hand in hand. When top manufacturers choose a specific machine or brand, it’s based on long-term reliability, after-sales support, technical performance, and the ability to adapt to growing demand. Reputable machine manufacturers often offer customization options, on-site installation, operator training, and prompt maintenance — all of which enhance user experience and peace of mind.

This commitment to quality machinery translates directly to product excellence on the shelves — something no serious food or beverage manufacturer can overlook.

The invert sugar syrup making machine has become a vital component in the modern manufacturing ecosystem. It represents more than just an upgrade — it’s a transformation in how sweeteners are produced, controlled, and scaled.

Top manufacturers trust these machines not just for their impressive performance and output but for the critical role they play in ensuring product quality, hygiene, and consistency. As the demand for invert syrup continues to rise across industries, investing in the right machine isn’t just a choice — it’s a competitive necessity.

3. What industries use invert sugar syrup making machines?

Invert sugar syrup making machines are widely used in industries such as confectionery, bakery, soft drinks, dairy, jams, pharmaceuticals, and processed foods, where high-quality liquid sweeteners are required for production.

4. What are the key benefits of using an invert sugar syrup making machine?

The key benefits include increased efficiency, consistency in product quality, precise control over syrup production, reduced human error, and improved hygiene. These machines help manufacturers maintain uniform syrup texture, sweetness, and overall product quality.

5. How can invert sugar syrup making machines improve production efficiency?

These machines automate and streamline the syrup-making process, reducing manual labor and production time. With precise controls for temperature, mixing, and filtration, they ensure high-quality syrup is produced faster and with fewer errors, leading to improved overall production efficiency.